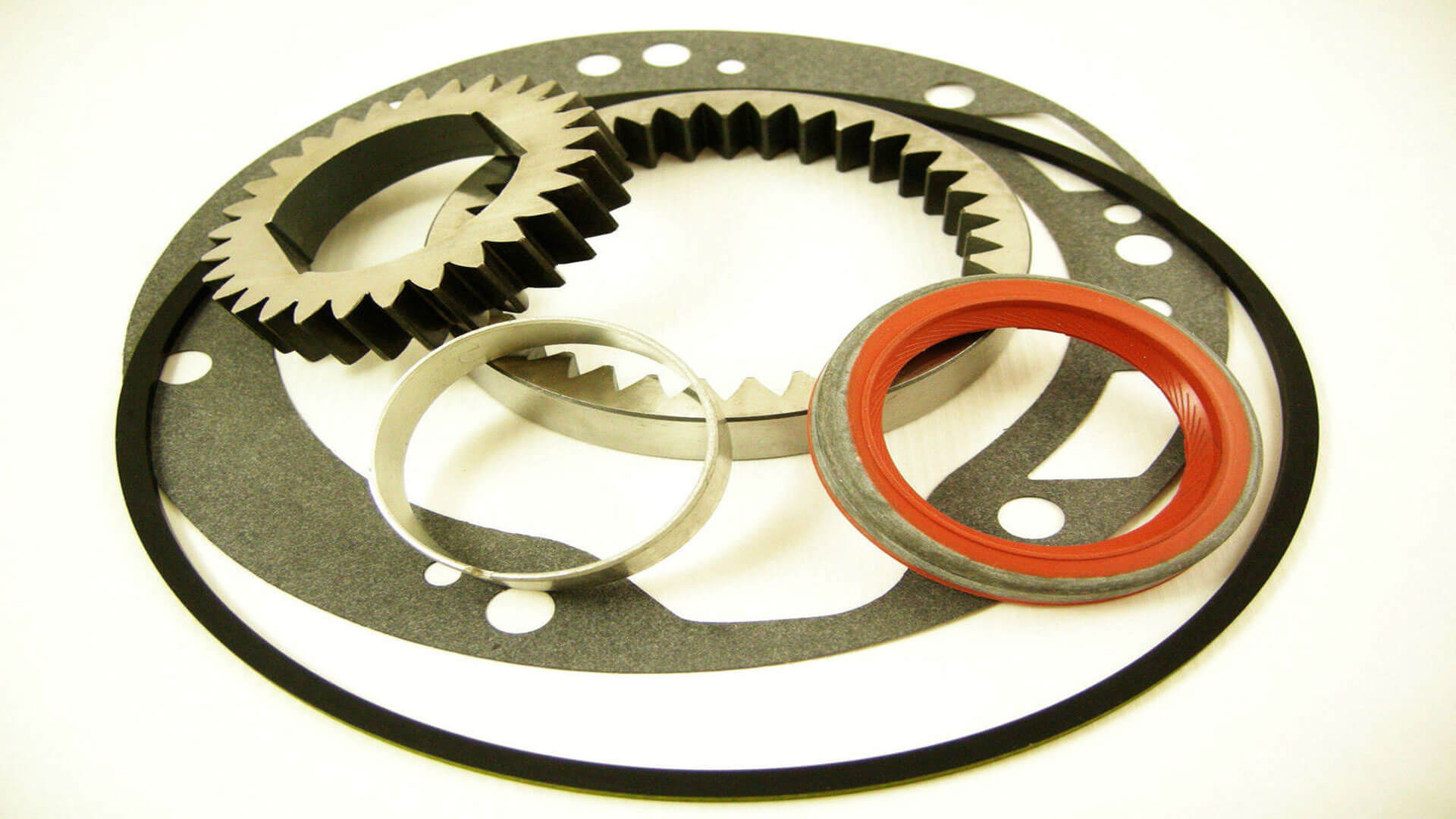

C4s are tough cars, but even they need help when being put through their paces on the street or racetrack. Shift improvement kits from Trans-Go or B&M Racing & Performance provide reliable shift improvements by reducing clutch slippage and band burn – perfect for improving shifting.

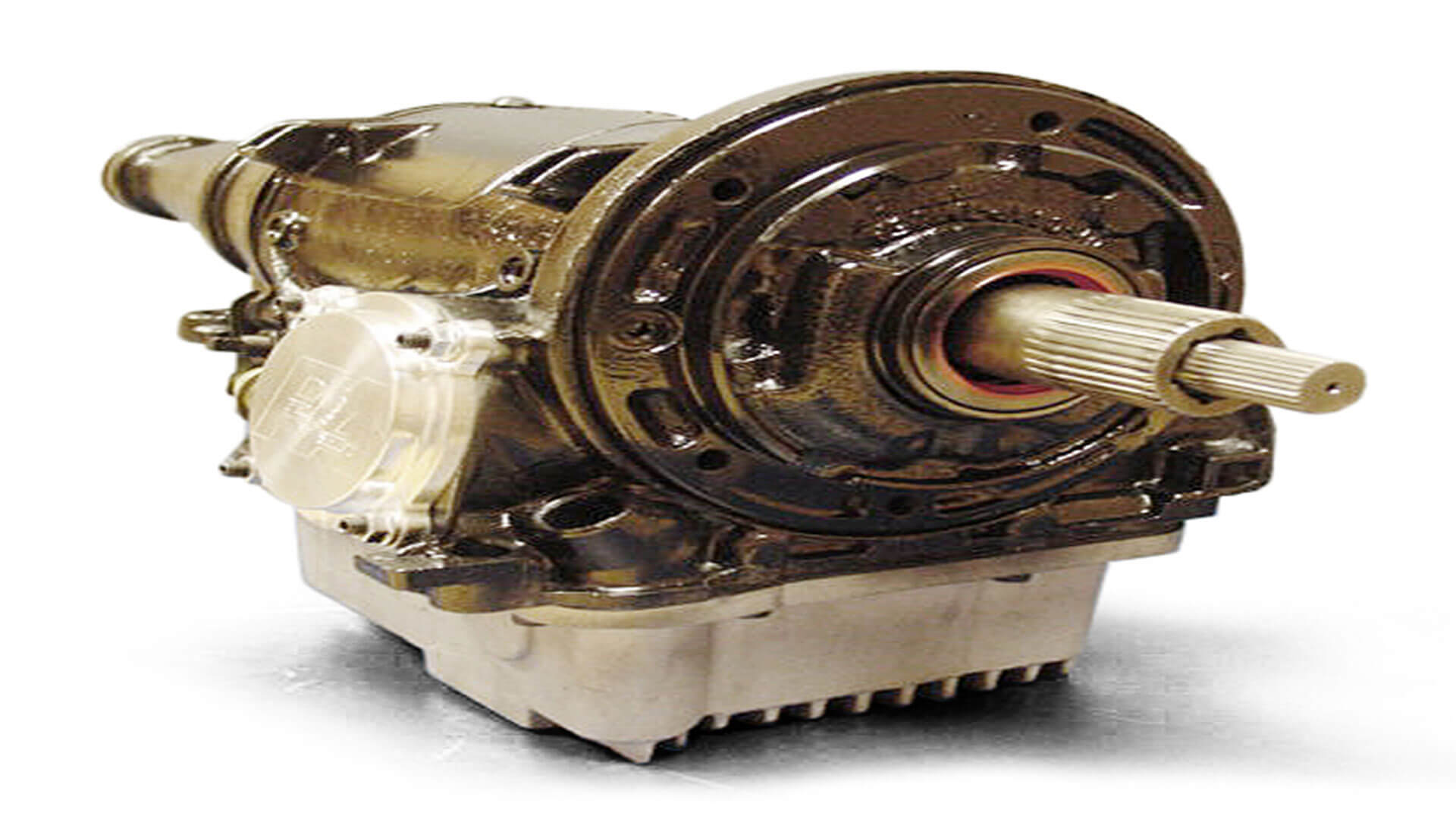

Experienced transmission builders favor stepped bell and case-fill C4 transmissions for compact and intermediate Fords and Mercurys, providing better dipstick tube and header clearance.

Case and Bellhousing

Ford first introduced the C4 automatic transmission – or cruise-o-matic – in 1964, giving drivers two driving ranges depending on how you set the gear selector.

Originally equipped with Dual Range shift patterns that provided two distinct driving experiences depending on which gear selector was activated.

The C4 transmissions were significantly lighter than their 2-speed predecessors due to lightweight aluminum components and an easier Simpson planetary gearset, making these light-duty transmissions popular with hot rodders and drag racers and still used today.

The C4 was available both as pan-fill and case fill configurations. A pan-fill unit can be identified by counting the bolts that secure its oil pan to its case itself; case-fill units feature a push-in dipstick while pan-fill units require screws instead. Pan-fill units were designed specifically to work with FE big blocks in trucks and cars, whereas case fill units can accommodate small block engines such as 351 Clevelands in passenger cars.

Input Shaft

The input shaft connects your engine’s power to your gear section and must withstand an immense amount of rotational torque for it to function effectively. Therefore, its durability must be ensured.

Metallographic analysis of the fractured component revealed secondary and incipient intergranular cracking at the bottom of adjacent dot peen lettering, indicative of high residual stresses that had led to fragile surface conditions. This type of cracking indicates brittle surface conditions caused by high residual stresses.

Chemical and hardness testing on an input shaft from a No. xx car revealed it was constructed of 300M ultra-high strength alloy steel likely carburized for carburization with a Rockwell hardness of 54 HRC at its initiation region; two fatigue events occurred nearby this region prior to final torsional overload failure. 1964-1969 C4s used an input shaft and clutch hub equipped with 24 splines on both ends; from 1971 on, however, these were upgraded with an upgraded input shaft of 0.839 inch diameter and 26 spline clutch hub for improved durability.

Torque Converter

Torque converters are fascinating pieces of engineering; they convert mechanical power to electrical energy for use by planetary gear systems, providing your stall speed and gear shifting capability while also contributing to fuel efficiency.

Ford utilized several types of torque converters; when pairing your C4 with a stock engine, make sure the torque converter matches up perfectly with it to avoid ruining its transmission. Install a high-temperature thread locker on pump bolts to help maintain proper torque; additionally install the governor filter so as to protect governor operation from particles entering from outside sources. Assembling your C4 build requires closely inspecting every part for wear and scoring; often overlooked factors are at the root cause of many failures such as worn seals or loose components – for instance drag racing builders often suggest using Kevlar bands which don’t function well on street roads!

Clutch

As well as providing power from the engine to the gear box, the clutch helps reduce vibrations and ensure smoother operation of your transmission. Furthermore, this part helps prevent heat build-up within it that can result in costly breakdowns.

The pressure plate applies a clamping force to a friction disc mounted to the flywheel through splined hubs. When clutch pedal is depressed, pressure plate and flywheel rotate together gripping driven friction disc between them until released from clutch actuation by diaphragms or springs in main casting that lift off of driven disc.

Ford initially designed its C4 with a green dot dual-range valve body capable of handling 350 lb-ft of torque. Later, however, Ford released a revised model featuring a Select-Shift control panel offering P-R-N-D-2-1 shift pattern capability.