C4 transmissions are straightforward light-duty transmissions you can easily rebuild in your own shop, making them great candidates for street/strip use. A shift improvement kit such as B&M or Trans-Go can assist with increasing reliability by firming up shifts and decreasing band and clutch slippage.

Experienced builders tend to favor stepped-bell pan-fill cores over blended bell versions that only fit compacts and intermediates, as these bolt directly to the case instead of having to use front pump mounting points.

Shifting Gates

Interested in upgrading the performance of your classic vehicle for street or strip driving? Check out this B&M Sidewinder Z-Gate Shifter (80681). It features reverse lockout capability that complies with both NHRA and IHRA requirements, plus comes complete with neutral safety switch, black plastic T-handle handle, and 5-foot cable – everything needed for street or strip performance!

The patented design eliminates any chance of accidentally shifting into reverse while moving up through the gears, and allows a driver to rapidly transition between first and reverse for off-road situations. The shift arm points up at 11 O’clock as an indicator for Park, and when pulled back through 12 O’clock is used to switch from Reverse into Neutral then Drive; pulling forward moves it back into Park again. Gate plates give this shifter a solid and rugged feel with smooth operation without jamming or binding up for responsive shifts from driver.

Lever Length

The lever on a shifter should move freely from its position in the car to where it sits on the transmission for setting shifting patterns. If something prevents this movement, or its link rod does not line up correctly, something must be in its way and cause interference to this process.

One method for checking neutral safety is to unthread the shifter clamp nut with its long hole and pull back on the selector lever on your transmission until the neutral safety switch engages – though this should be difficult, it should serve to verify whether or not neutral safety works correctly.

Lokar’s floor mount shifter is an exceptional, user-friendly product featuring a 4′ push/pull cable with durable 1/4″ inner cable and spherical rod ends for smooth operation. It can be mounted virtually any where front to back allowing it to take advantage of existing floor openings or create unique mounting locations; additionally it comes in various lengths.

Shifting Lever

The handling mechanism 13 of the C4 transmission shifter includes a shift lever 12, an auto-reverse mechanism 37 for it and a rotation mechanism 38. The L-shaped shifting lever 12 can be rotated freely around one of its support boards 17 in forward/backward directions using auto-reverse mechanism 37 while also being supported rotatably via spring 57 located on its lever-side.

Rotational movement of the shift lever causes first and second axles 18, 19 to rotate at a fixed angle of 45 degrees in this embodiment, followed by pressing of guide 15 by thrust part 30 of fourth cam 10 so roller 16 moves in reverse and gear shifts to neutral.

Determine whether the shift lever features a twist type cable. If this is the case, place the lever into its most relaxed cable position before removing its cover and unscrewing any screws holding the wire end to the lever body; usually this requires using a hex wrench for removal.

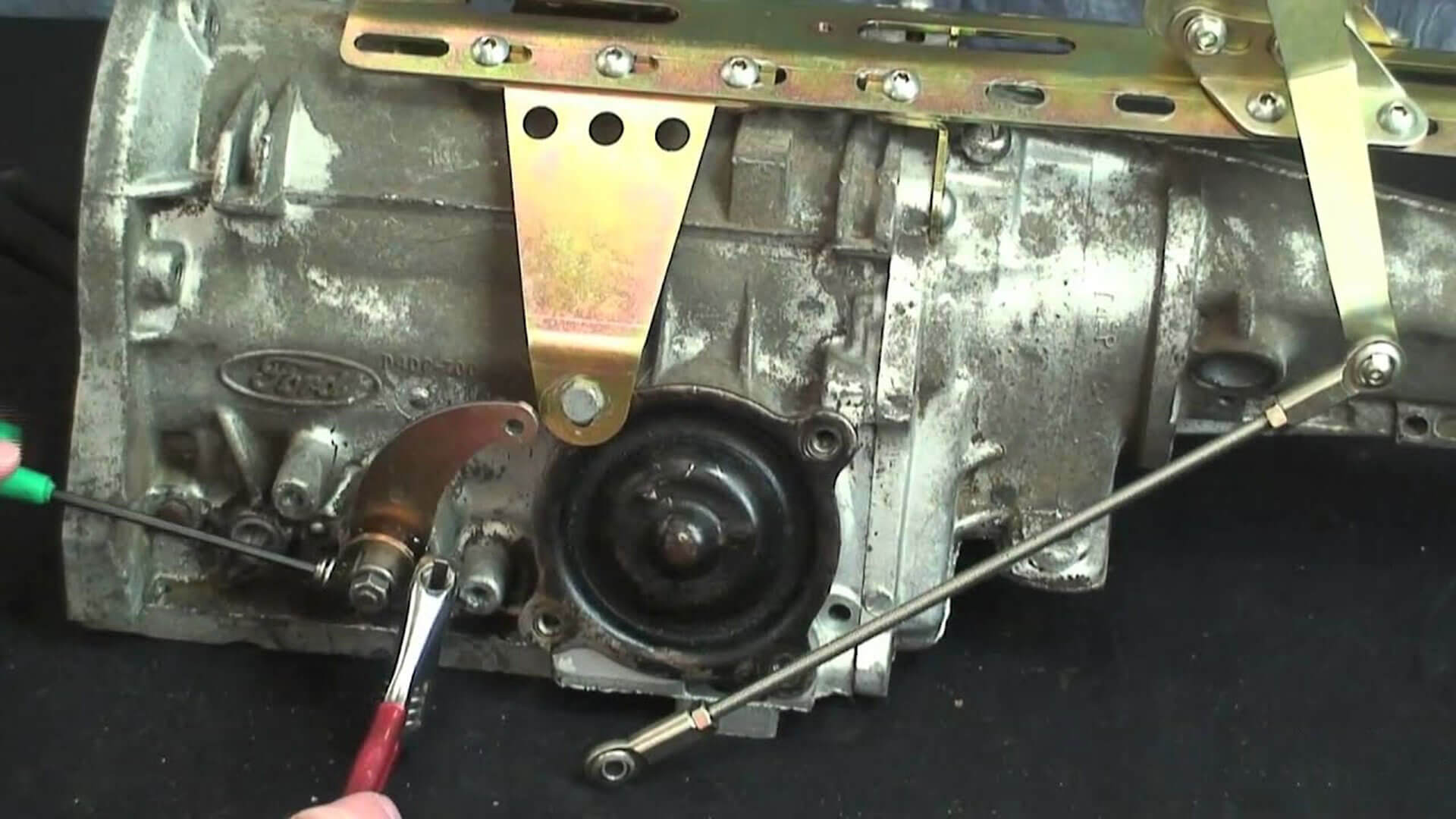

Cable Bracket

The Ford C4 and C6 automatic transmissions have become immensely popular with car enthusiasts due to their simple operation and durability, both of which have undergone various upgrades that have increased performance from when they were originally released.

C4 originally debuted as the Select-Shift or Cruise-O-Matic transmission for 1964 model year vehicles and served as a light duty replacement of Ford-O-Matic two- speed transmission using cutting edge Simpson compound planetary gear set technology.

To identify a C4 among all other Ford automatic transmissions, look at its bolt pattern of the pan dipstick tube. Most C4s used a blended case and bellhousing with a 164-tooth flexplate for full-size car and truck applications while some pan-fill models featured notched cases and 148-tooth flexplates for pan fill applications.